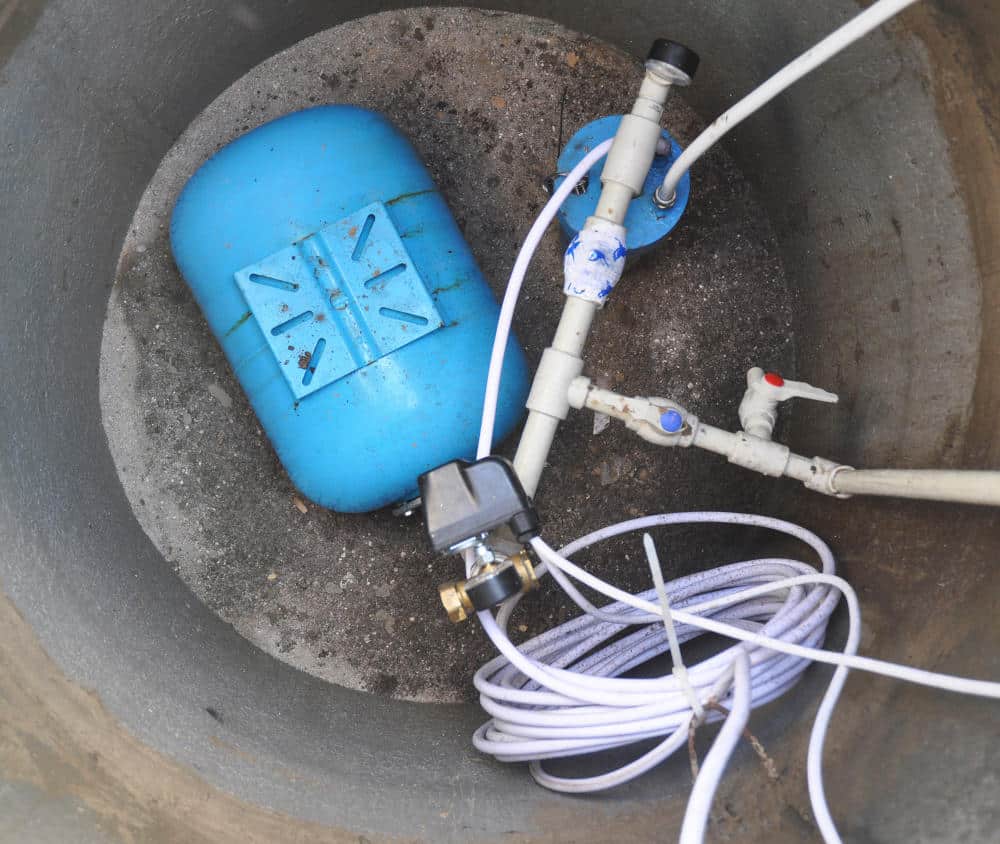

A water well pump is an essential component of your water system, ensuring that clean water is delivered efficiently to your home or property. However, like any mechanical system, well pumps are susceptible to wear and tear, especially when certain factors come into play. Understanding the most common causes of well pump failure can help you take preventative measures and ensure an uninterrupted water supply. Below are five common causes of well pump failure in Arizona and how to avoid them.

1. Low Water Table

One of the leading causes of well pump failure in Arizona’s dry climate is a drop in the water table. When groundwater levels decline, your pump has to work harder to draw water, putting strain on the motor and increasing the likelihood of failure. This often happens during periods of drought or due to excessive groundwater use in the area.

Prevention Tip: Regularly monitor the water levels in your well, especially during the summer months. Installing a low-water cutoff switch can also protect your pump by automatically shutting it down if the water table drops too low.

2. Power Surges

Power surges, often caused by lightning storms or electrical issues, can damage your well pump’s motor or control box. Even a brief surge can short-circuit the system, leaving you without water until repairs are made.

Prevention Tip: Install surge protection devices designed specifically for well pumps. Additionally, turning off the pump during severe storms can protect it from electrical surges.

3. Clogged or Dirty Filters

Sediment buildup and clogged filters can force your well pump to work harder to maintain water flow, leading to premature wear and eventual failure. Wells that draw water from areas with high sediment content are particularly vulnerable.

Prevention Tip: Schedule regular maintenance to inspect and clean your well system’s filters. Installing a sediment filter at the wellhead can also help reduce debris that reaches the pump.

4. Overworked Pump

Well pumps that are too small for the property’s water needs or that run continuously due to a malfunctioning pressure switch can burn out quickly. Overworked pumps are prone to motor failure and may need frequent repairs or replacement.

Prevention Tip: Ensure that your well pump is sized appropriately for your household or property’s water usage. If your pump is cycling on and off frequently, have a professional inspect the pressure switch to avoid overworking the motor.

5. Corrosion and Rust

Arizona’s groundwater can contain minerals that accelerate corrosion, particularly in older metal well pump components. Over time, rust and corrosion can weaken the pump housing, impellers, and other parts, leading to leaks or total failure.

Prevention Tip: Upgrading your well pump to a newer model with corrosion-resistant materials, such as stainless steel, will minimize the damage of rust and corrosion. Routine inspections to check for rust or wear can catch problems early before they lead to system failure.

Your Partner for Pump Repair in the West Valley

Well pump failure can lead to significant inconvenience and costly repairs, but many common causes are preventable. Regular maintenance and proactive monitoring can extend the life of your well pump and keep your water flowing smoothly. If you’re experiencing issues with your well pump, contact Arizona Pump Services for professional pump repair and maintenance solutions.